Building a customized 3D pump to work off of low-voltage sources

Overview

While Pure Paani is focusing primarily on developing a series of hand-powered water filtration devices, the feasibility of low-wattage, motor-powered devices is worth considering. Most gravity filters can provide a flow rate of less than 0.1 liters per minute. It is possible to achieve the same standard of filtration with an increased flow rate by attaching a typical gravity filter to a water pump.

Such a device would be most effective if it were powered by a typical USB phone charger. While this asserts the advantage of usability anywhere one could charge their mobile device, it includes the disadvantage of lower power availability. That is, the pump would have to run off a voltage no more than 5V, and a current no greater than 1A. For those that are curious, this information can be found on the fine print of any typical USB charger. For example, the charger on the left provides 5V at 1A while the one on the right provides 5.2V at 1.35A.

Specifications

Many pumps with similar specifications are available on the market. For example, a typical aquarium water pump can run off 6-12V and a current less than 1A. However, most of these function by being submerged in the water. Therefore, the objective of this project was to develop a water pump with the following product specifications:

- works on the exterior of the liquid being pumped

- requires no more than 5V, 1A of supply

- induces a flow rate of at least 1 liter per minute through a 0.1 micron filter

- connects to a typical bottle of drinking water as the inlet reservoir

- is manufactured affordably

- assembles quickly

The primary method of manufacture during this prototyping stage was to purchase standard parts in Bangalore and to 3D print the pump parts. Admittedly, such methods don’t lend well to low-cost manufacture, but this was allowed given this device’s proof-of-concept stage.

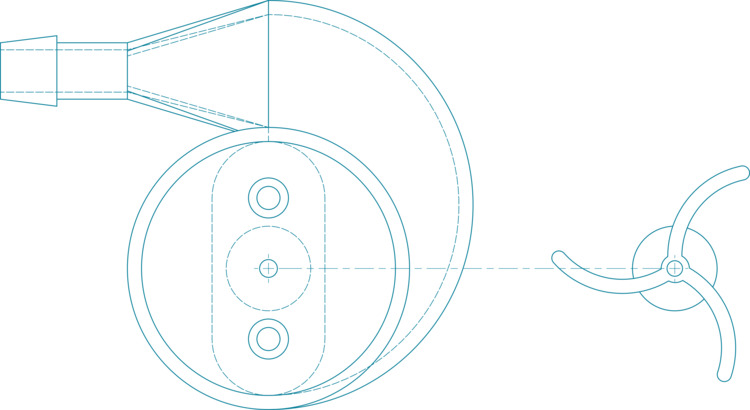

A centrifugal pump allows for a quick and easy assembly given its basic enclosure/impeller arrangement. This is as opposed to a diagram pump which requires a chamber of cyclically increasing/decreasing volume as well as a system of inlet-outlet check-valves. While Pure Paani uses the latter type for almost all of its hand-operated devices, the former was used because of its suitability for motor attachment.

Manufacture and Assembly

Printing Enclosure

The first step was to print the centrifuge body. As shown, the part was produced with some minor defects. It should be disclosed that this is Pure Paani’s debut in 3D printing methods, so some mistakes are that of a novice. For example, the messy strands on the right-ward protrusion are likely due to a cylindrical cavity being printed parallel to the printer bed.

Cleaning Enclosure

The enclosure was then cleaned up as best as possible. This did however leave some pretty serious imperfections, particularly the lack of a water-tight seal needed to function properly.

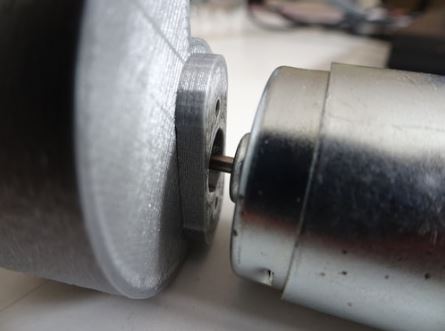

Attaching Motor

The second major issue was the improper fit between the motor and the feature on the body where it was supposed to insert. This was likely due to contraction post printing. While future prints will take this effect into account, it’s worth admitting that the initial measurements themselves could have been taken more carefully.

Printing Impeller

The next step was the printing of the impeller itself. As shown, this part suffered the same problematic strands as the enclosure. More research will be carried out on how to avoid this issue in the future. This image also shows the extra base layer which was intentionally added.

Preparing Impeller

After some quick clean up, the impeller was in decent shape. The hole for the shaft in the center also needed to be drilled out to a slightly larger diameter.

Inserting Bottle Cap

A water bottle cap was then inserted at the pump’s inlet. This step required a healthy mixture of gentle coercion and blunt force. Future versions will incorporate the female threads directly into the printed model.

Completing Assembly

A water bottle was then inserted into the embedded cap. Finally, an outlet hose was attached to the barbed outlet. The other end of the hose was then connected to an enclosed gravity filter from Village Water Filters.

Testing

The device was then tested in a nearby sink. While it worked surprisingly well for a proof of concept, it was simply too leaky. This negatively impacted its convenience and safety. While the low voltage of the motor didn’t pose a serious hazard, it’s always good form to avoid mixing electricity and water (in most applications).

Performance

In conclusion, this first iteration of the design-build-test cycle went pretty well. However, given the design constraints initially set forth, there was a lot of room for improvement.

- Works on the exterior of the liquid being pumped

- accomplished – though very leaky

- Requires no more than 5V, 1A of supply

- unaccomplished – worked somewhat at 5V, 0.13A but full flow shown near end of demonstration video was at 12.2V, 0.17A.

- Induces a flow rate of at least 1 liter per minute through a 0.1 micron filter

- unaccomplished – forgot to test, appeared to be less than 1 LPM

- Connects to a typical bottle of drinking water as the inlet reservoir

- accomplished – though very leaky

- Manufactured affordably

- unaccomplished – constraint waived

- Assembles quickly

- accomplished – assembly process could be under a minute

Moving Forward

In developing this idea further, Pure Paani plans to

- Learn more about 3D printing water-tight parts. Any advice on this subject is more than welcome at Chris@PurePaaniIndia.com.

- Research motors that offer higher speeds at 5V.

- Research market-available diaphragm pumps.

However, it’s worth noting that even if the pump were completely water tight and provided a better flow rate at the prescribed power rating, the user would still be constrained to some source of electricity, whether it be an outlet, a battery bank or a solar panel. While this reduces operator fatigue, it constrains them either spatially, technologically, or both. That is, the development of a motor-operated pump may be a fruitful endeavor, but there are restrictions to such an approach that are unavoidable.

Recent Comments